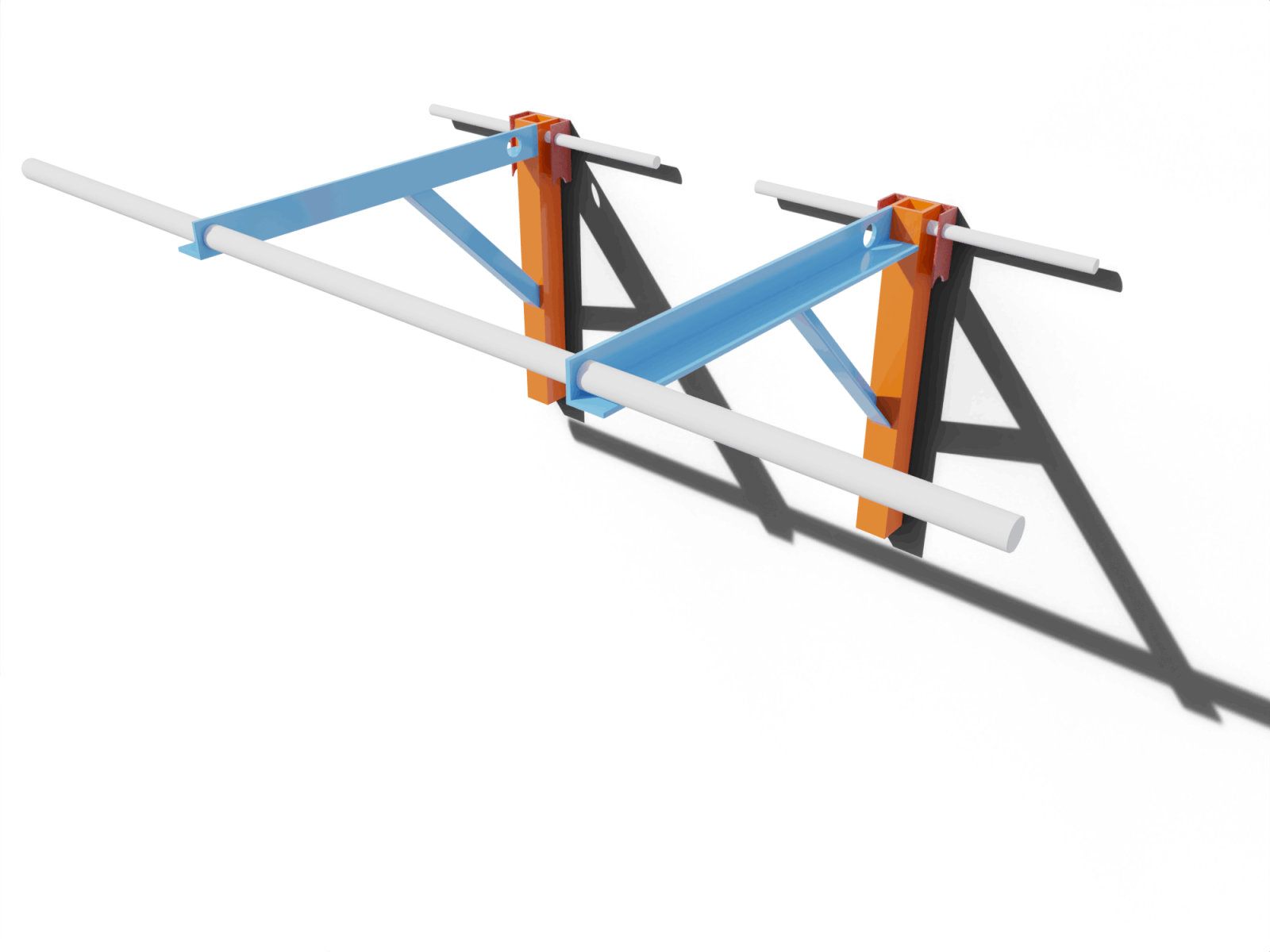

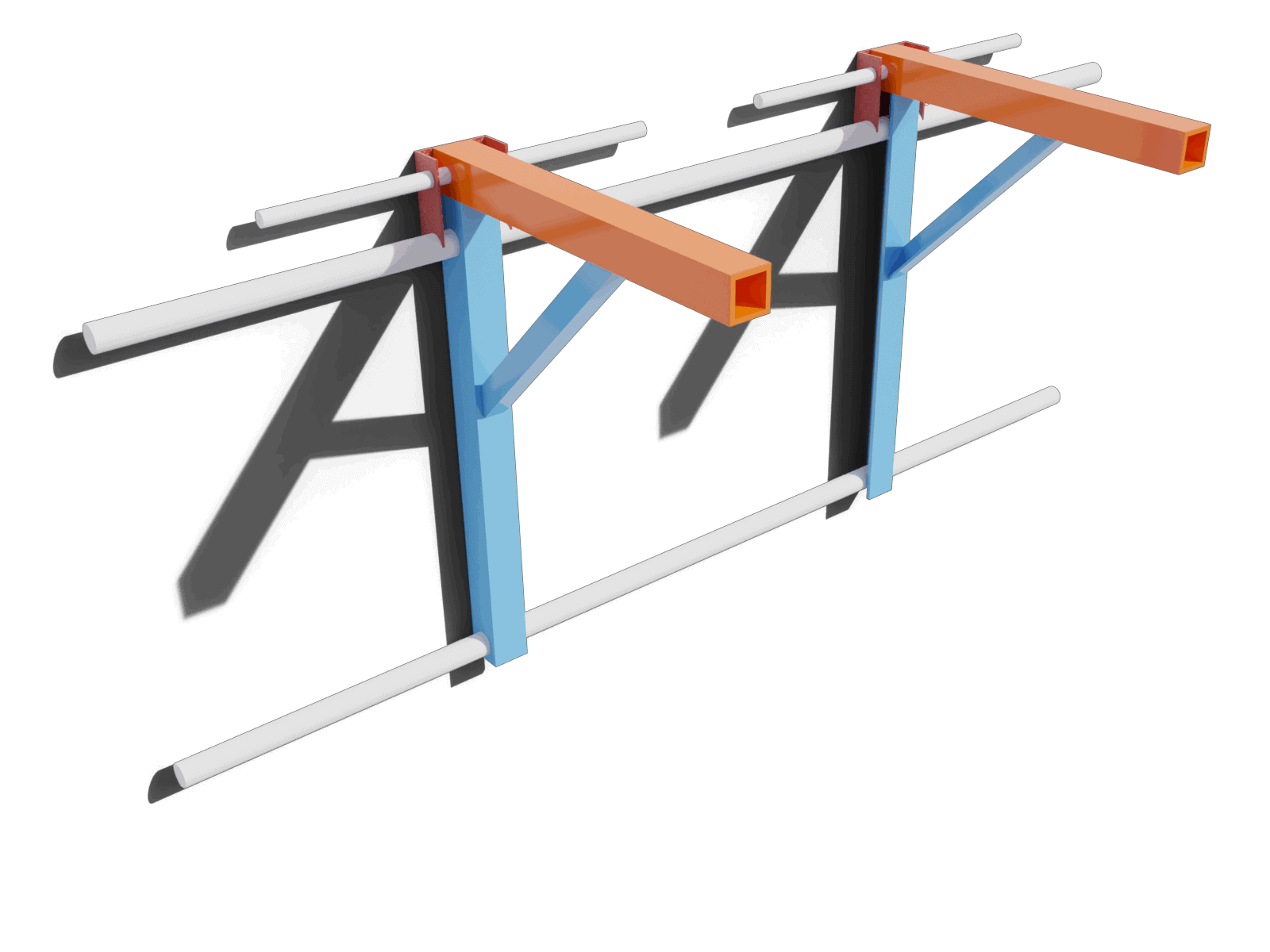

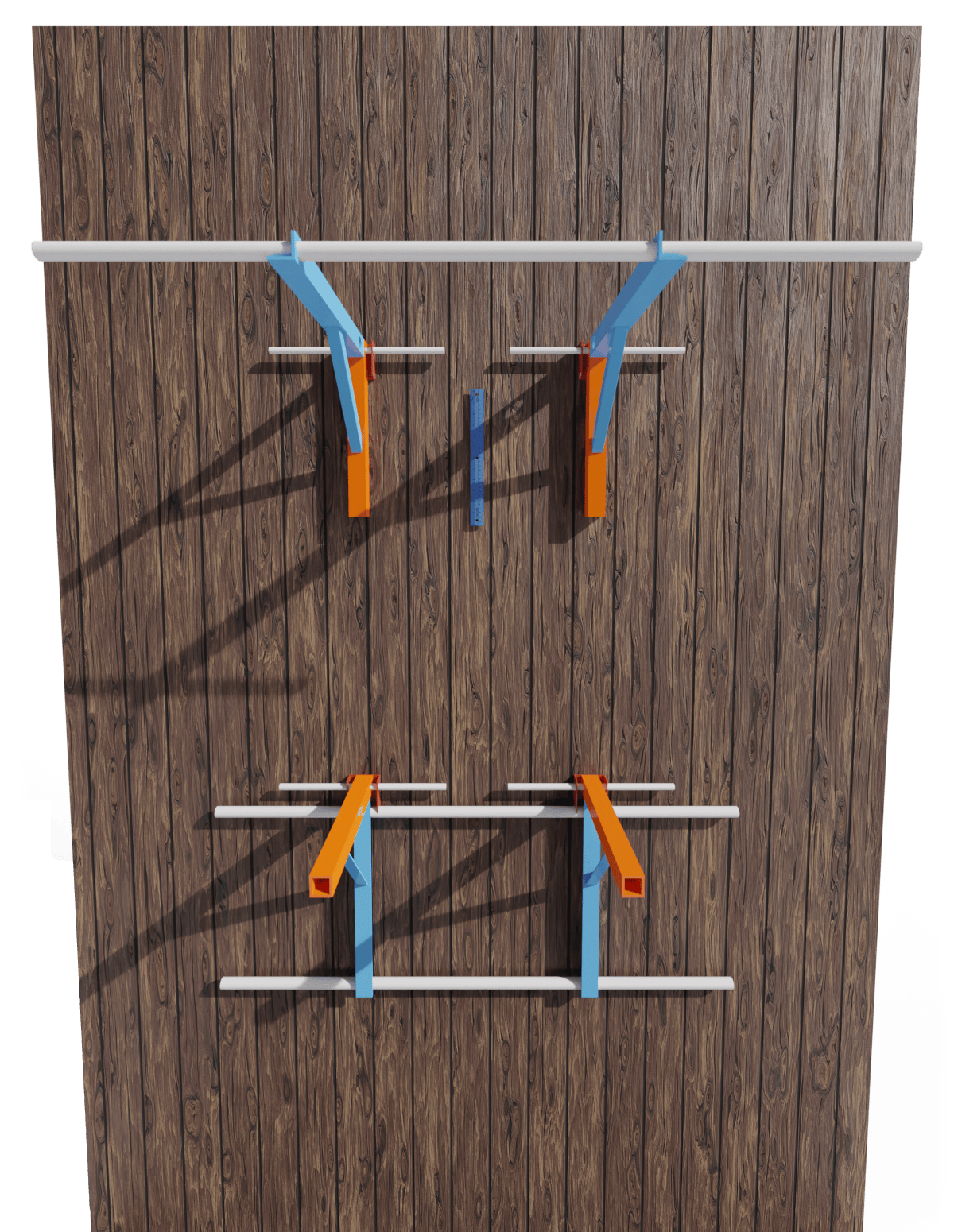

Product Renders

Something I came up with when I couldnt find an elegant solution for an unified pull-up & dips exercise equipment.

Something I came up with when I couldnt find an elegant solution for an unified pull-up & dips exercise equipment.

The Thought Process

My critereon for the perfect piece of hardware boiled down to modulatiry.

At first I needed something that took up the least amount of space. This meant a single unit had be compatible with both over head exercises and dips. Being modular would also help someone remove the hardware without powertools should it ever pose as an obstruction.

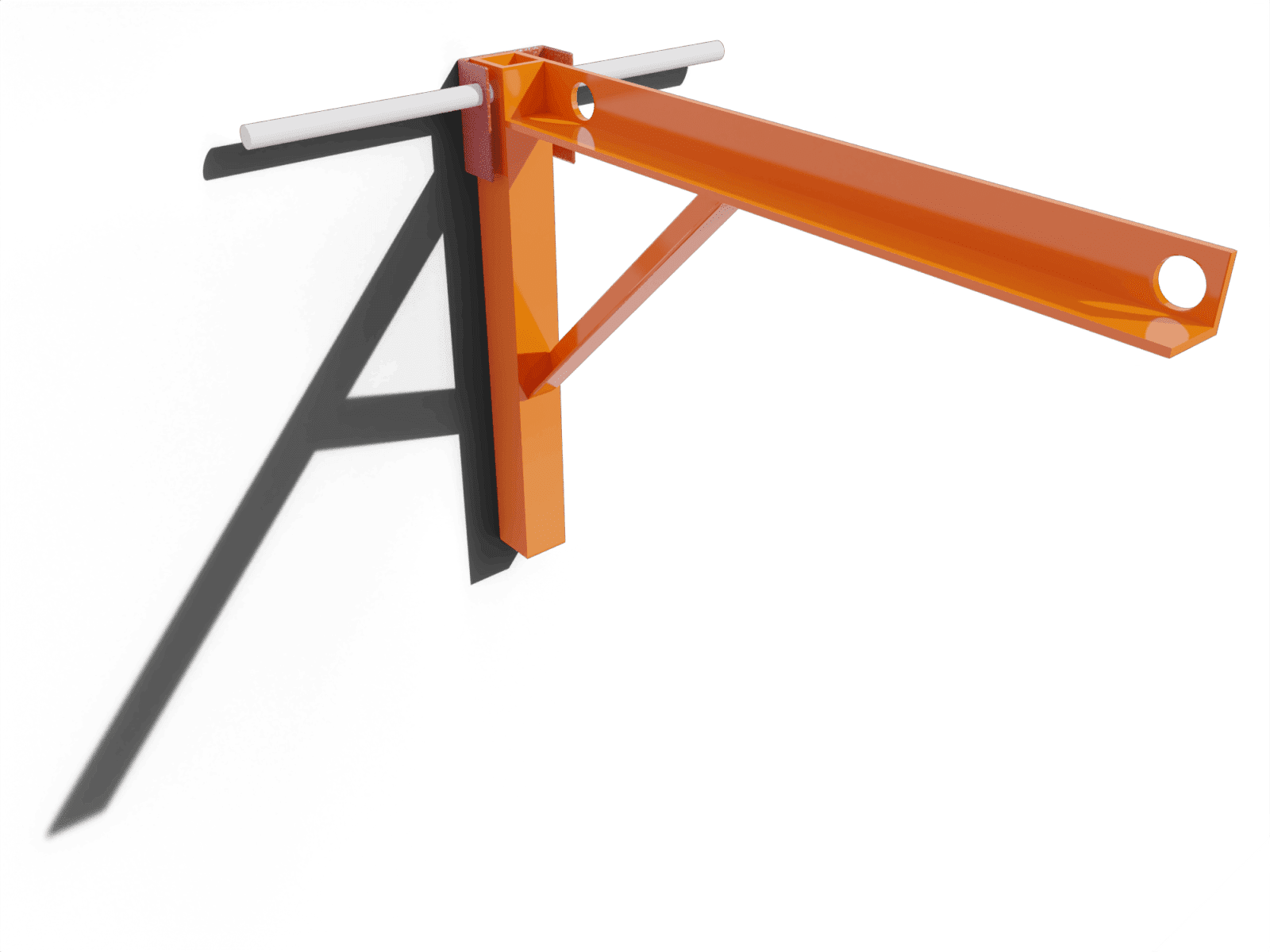

When I decided I would design one tailored to my needs, I wanted to decrease the number of variables to make the fabrication process simpler. This meant using industry standard parts and making the actual modules homogeneous i.e. using the same metal to avoid complexities in welding and structural integrity. As it would be in some way attached to a wall, I also needed to make sure to caliberate the tensile and shear forces on the anchors.

To verify my napkin maths, I ended up doing a conducting some FEA on the final designs.

Making the models and specifications

The model mesh and its environment was made in blender. To ensure compatibility with other softwares, the primary model was made by conducting boolean operations on primitive solids. For fine tuning and simulations, it was then exported in a .stl format to be read by an FEM capable software.

The model mesh and its environment was made in blender. To ensure compatibility with other softwares, the primary model was made by conducting boolean operations on primitive solids. For fine tuning and simulations, it was then exported in a .stl format to be read by an FEM capable software.

[Dimensions]

Dowel radius: 1.27cm / 0.5 inch

Dowel mounts (L-Section): 50cm long EA 40x40x5

Brace (L-Sections): 15cm long EA 25x25x4

Dips arms (Square Hollow Section): 40cm long SHS 40x5

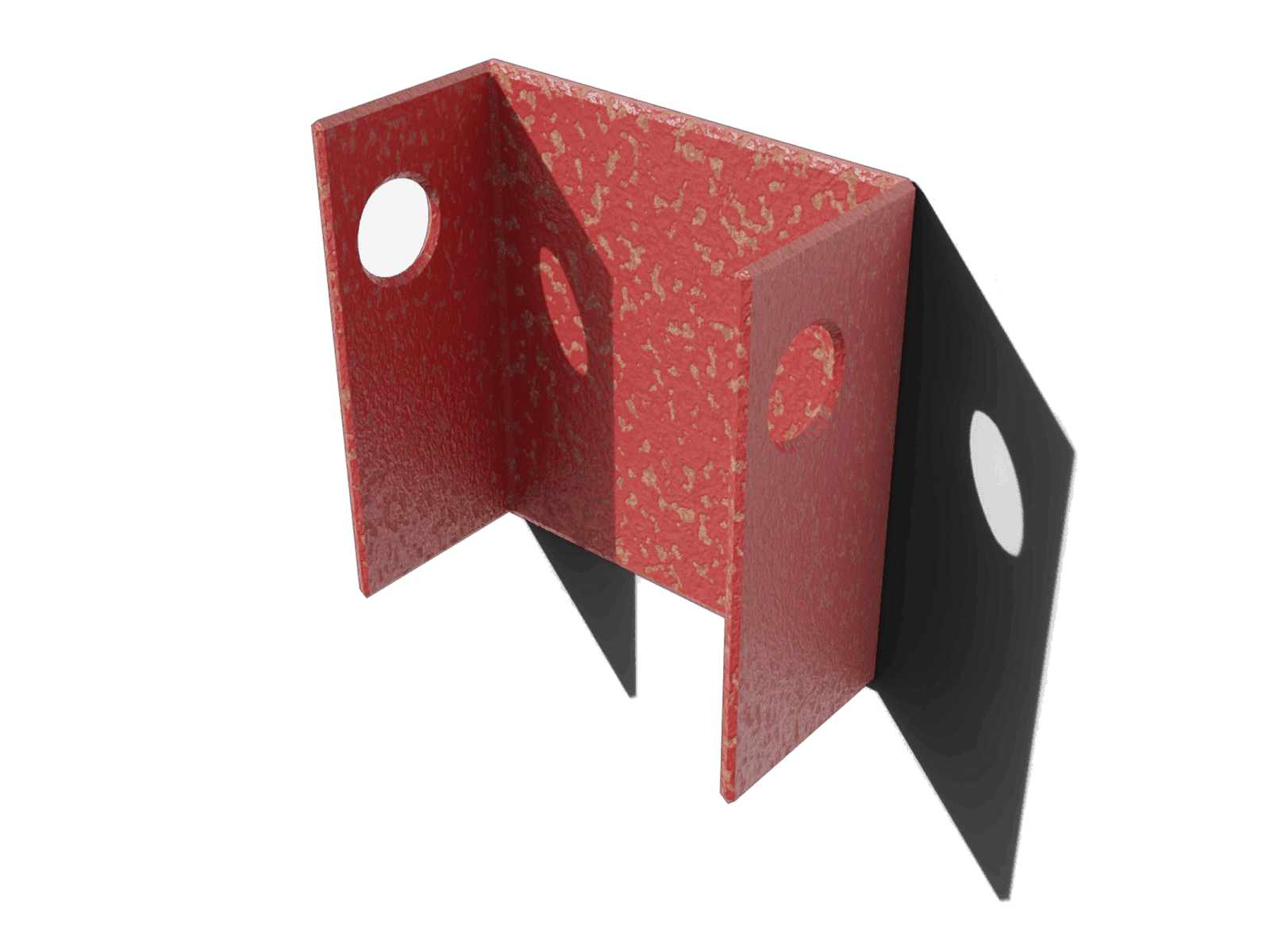

Anchors (U-Sections): 8cm long 75 PFC

Anchor radius: 0.83cm / 1/3 inch

Top anchor: 2.28cm / 7'6 (pullups)

Bottom anchor: 1.25m / 4'1 (dips)